D.J. Scheffler & Nye First to Be Highlighted in DFI's 2020 Spotlight

/“PEER TO PIER” CONSTRUCTION

BUILDING THE NEW SCORPION PIER ON SANTA CRUZ ISLAND

For the next six to nine months, the crew will be working with their peers from Jilk Heavy Construction. This peer to peer approach allows D.J. Scheffler & Nye to share their equipment and deep foundation drilling knowledge to help build a more efficient access point for National Park visitors for years to come.

A TEAMWORK APPROACH

Preserving and restoring balance to Santa Cruz Island’s naturally functioning ecosystem is a prime example of teamwork in action. It took a combination of organizations and disciplines from scientists, naturalists, botanists and park rangers working together over time to help protect the island’s natural and historic resources.

The same approach to teamwork is evident as deep foundation drilling experts D.J. Scheffler & Nye work together with their peers from Jilk Heavy Construction in the construction of the new 300-foot pier for Scorpion Cove. Both firms have established camp on the island for the coming months to complete the project.

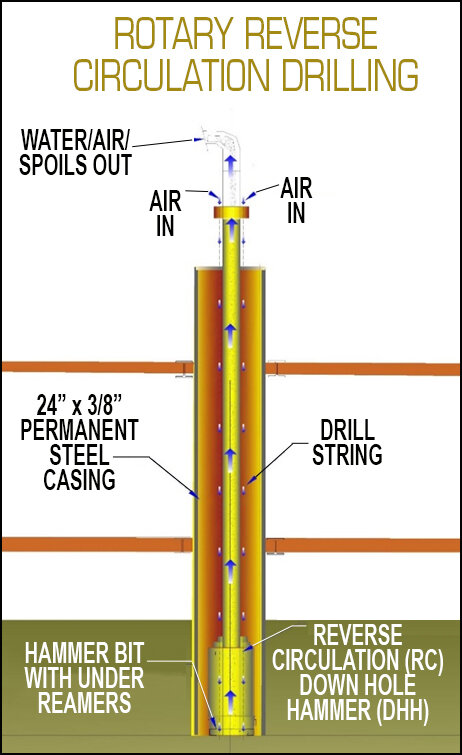

The peer to peer combination allows each company to take specific roles in the project for job and cost efficiency. D.J. Scheffler & Nye provides the technical expertise and training needed while using the Reverse Circulation Down the Hole Hammer for the installation of the permanent steel casings required for all the pier support piles. Reverse Circulation (RC) Drilling is considered the most versatile and reliable system for this type of construction. The ability to pulverize dense sediment and sand, hard rock cobbles, and boulders in one continuous stroke is a groundbreaking advantage. At the same time, the cuttings are removed up the center of the bit and drill pipe which makes for a quicker and safer process. This combination of superior production rates with the rapid removal of cuttings results in significant cost savings.

For this project, D.J. Scheffler & Nye will use the RC Drilling Down the Hole Hammer to install a total of 81 piles (24-inch diameter permanently cased) to a depth of 31 feet. This will include pier support piles, berthing piles and lift platform support piles. Construction will start at the shore side and be built bent-by-bent progressively in the offshore direction. As the elevation slopes downward to greater depths offshore, the unsupported pile lengths above mudline will vary, ranging from 5 feet at shore side to 40 feet above mudline at the pier's furthest offshore end. The final result will be a superstructure designed to handle storm events and wave action, as well as improving the safety and efficiency of loading and offloading passengers and cargo.

With over 65,000 annual visitors to the island, the time was right for a new pier to provide safer, more efficient and sustainable access for hikers, campers, boaters and snorkelers. The previous pier was not accessible during low tide and visitors had to use a ladder and form a bucket-brigade-style line to offload camping gear by passing items person to person along the pier gangway. The spirit of teamwork begun years ago lives on in the construction of this major improvement to critical Channel Island National Park infrastructure.

By sharing their technological expertise and using their RC Down the Hole Hammer, D.J. Scheffler & Nye will be instrumental in helping their fellow contractor keep costs down while finishing the project in a timely fashion. The project is truly an example of “Peer to Pier” Construction.